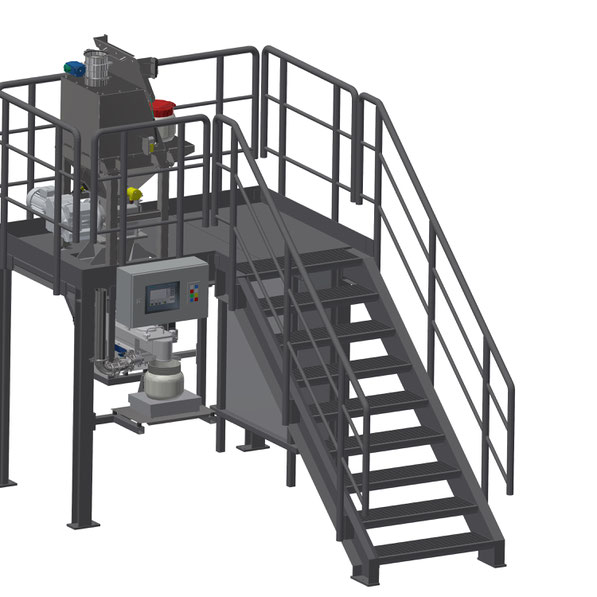

Typ: EDS-S / S / ZV-25

This automatic dosing and filling system, with integrated crusher, was designed and built for the automatic batch dosing and filling of clumped, crystalline chemicals. The partially clumped crystalline raw material is stored in bags or small drums and is manually filled into the feed hopper of the bag emptying station for the automatic dosing and filling process.

Before dosing, the crystalline raw material is crushed to the desired grain size using a crushing machine (nibbler). The crushed crystalline raw material is automatically gravimetrically dosed and filled into the weighed container packaging (screw can, drum) via a vibration dosing conveyor.

The design of the filling plant and the dosing equipment can be designed and manufactured tailor made corresponding to the specifications and procedural job definitions.

Application:

§ Chemical products

§ Powdery crystalline products

§ Granulate

Performance:

§ Voltage: 230 / 400 VAC

§ Drive power: 1,5-3,0 kW

§ Compressed air: up to 6.0 bar

Merkmale:

§ Package size: 5-20 l

§ Gravimetric dosing

§ Weighing range: 0-30 kg

§ Einfache Bedienung Operator-Panel

§ Prozessüberwachung